906-017 Carrera 6

Restoration:

The 906 designation has been used on four different and distinctive models. Certain variations of the 904, the "kangaroo" Bergspyder, the one off "Ollon Villars" hill climb special and finally the car most are familiar with, the Carrera 6. Over sixty were built allowing this version of the 906, or Carrera 6, to be homologated by the FIA as a sports car. However, two prototypes were constructed before the production run and did the bulk of the testing, and in the case of one of them, gave the new type 906 it's first international success.

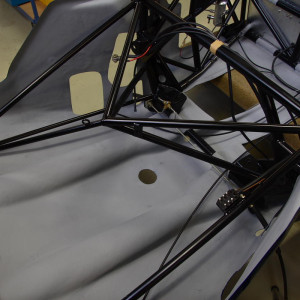

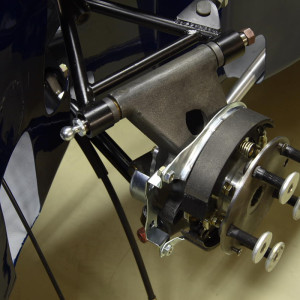

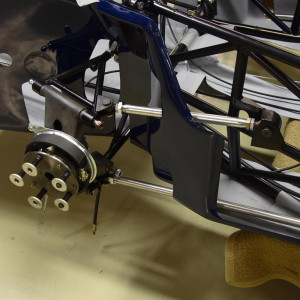

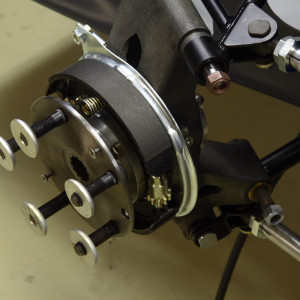

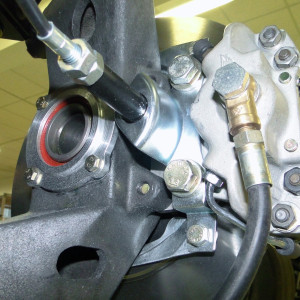

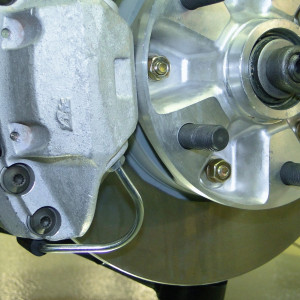

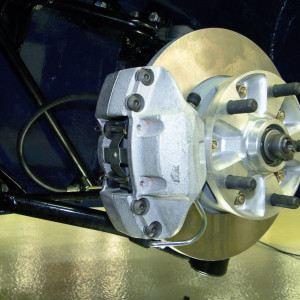

The true forerunner of the two 906 prototypes was 906-010, the Olllon Villars Bergspyder, a tube space frame covered with bodywork constructed of very lightweight fiberglass bonded to the frame. A set of Lotus Formula One uprights and 13" wheels were used not only to save weight but also to take advantage of the superior race tires offered.

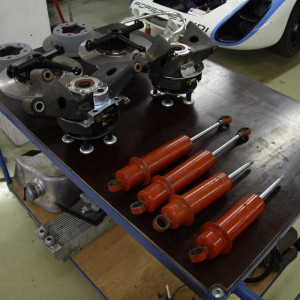

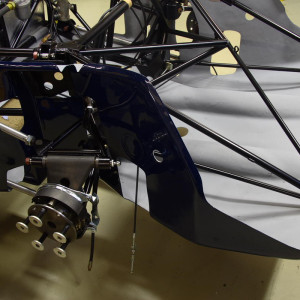

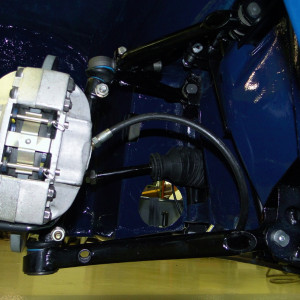

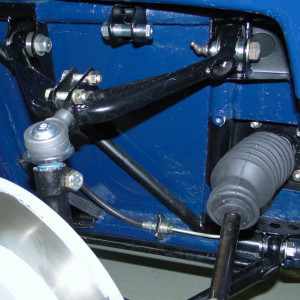

Ferdinand Piech arrived in 1965 and basically took over as the technical director. Within a short time he assembled a group of personal that would start with the 906 as the first true non road going competition model on up to the 917 project culminating in several world championships, and the overall important wins at Le Mans. The 906 was to be that beginning although a series of compromises were made such as using up the remainder of 904 suspension components in order to save costs. Piech had intended the 906 to use 13” wheels instead of the 15” as used on the 904. The first two prototypes were completed and running by November of 1965. 906-016 immediately was sent to the Volkswagen test track at Wolfsburg and was run in less than ideal circumstances to the point that 016 had to run Dunlop snow tires in order to continue testing. The second completed prototype, 906-017 was dispatched to the University of Applied Sciences in Stuttgart to under go testing in the full size wind tunnel. Previous tests had been done using a 1/5-scale model and while the original shape was promising, the results from the full size car would differ as was expected. The findings resulted in trying different aerodynamic set ups that would eventually be used on most of the 906 production run. However, development was to continue on the few 906’s that would be run as official werks entries with the focus being on further reliability, weight reduction and the introduction of fuel injection for the six cylinder 911 based 2.0 miter motor.

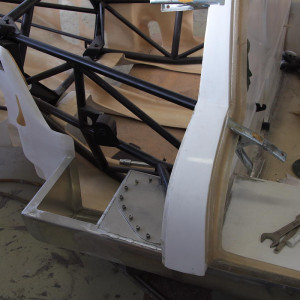

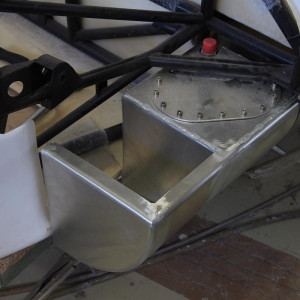

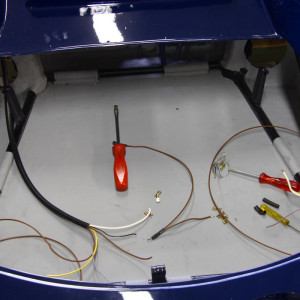

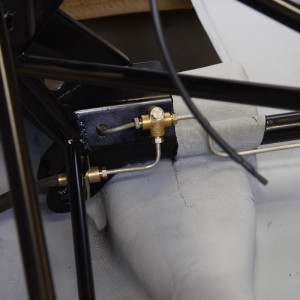

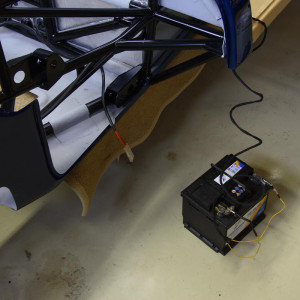

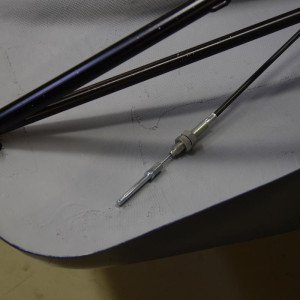

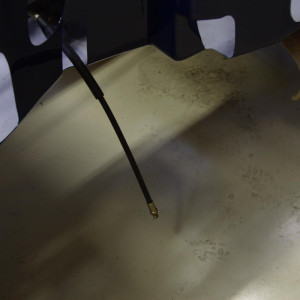

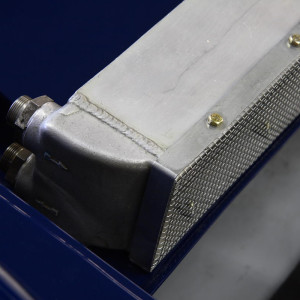

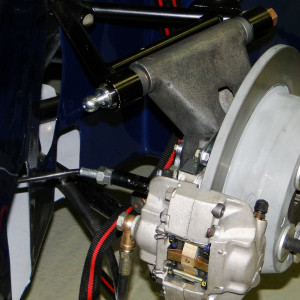

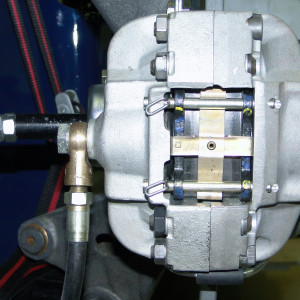

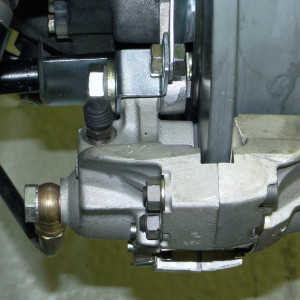

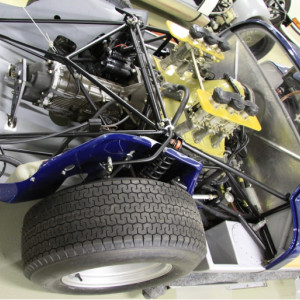

Testing in a stable environment such as a wind tunnel is a mandatory procedure but can not replace real time testing on a track just as testing can not substitute for actual competition. In late December of 1965 and in January of 1966, 906-017 was put through a demanding series of tests that showed some areas that had be addressed immediately. Flaws were found in the securing of the bodywork as 017 had the complete rear tail section come off and the door frames were not up to the task of remaining in place at racing speeds. Most critical though was a problem under acceleration that resulted in damage to the motor that was traced back to the oil tank. The placement and angularity of the tank caused air and not oil to enter through the lines. A newly designed oil tank was completed and along with a new motor, installed in 017 and a decision was made to enter 017 in the prototype category for the upcoming Daytona 24 race. Even with some questions over reliability of the new 906, the race was a complete success with 906-017 finishing in 6th position and showing no serious problems. Considering that the cars that finished in front of 017 had motors of 7 liter ( Ford GT 40 ) and 4.4 liter ( Ferrari ) the result is even more impressive. Upon return to the research & development department, 017 was stripped down and had all the major components checked. A series of cracks had developed during the Daytona race and were repaired and modified. After completion, 017 was used as the test bed for the installation of the new mechanical injected type 901/21 motor. This required new plumbing and the addition of a surge tank as well as a change to the electrics. A series of runs at Hockenheim showed increased flexibility with better torque and a quicker throttle response. With the all important Targa Florio approaching in May, 906-017 was sent along with five other series 906’s to Sicily. 017 was used as a practice car along with a six cylinder 904. This practice was to be quite eventful for the Daytona prototype as the pounding on the public roads caused the breakage of an axle shaft and two separate accidents, which caused major damage. One of the weak areas on the frame was the link bar under the gearbox and on later cars was replaced with a thicker wall tubing specification.

The purpose of the two prototypes, 016 and 017, was to further the development and identify the weaknesses that could be addressed on the production run. Both prototypes did their job admirably. 016 was used to introduce the Eugen Kolb designed langheck tail at the Le Mans trials while 017 saw actual battle at Daytona. Both cars contributed in as much as over one hundred modifications, improvements and upgrades were done to the cars that followed in production.

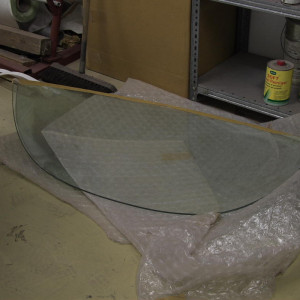

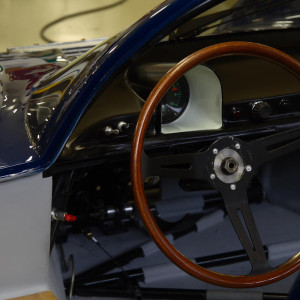

By September of 1966, an evaluation of all werks run 906’s had been done and those that were deemed useable and that could be refurbished were prepared and sold to private teams. Of the two prototypes, 017 had the much harder life between testing, practice and competition. The frame was poor condition and the body was in need of considerable repair. 017 was eventually sold as a parts car less motor and ended up in Southern California in the early 1970’s and was taken to Mexico for a few years before returning back to California. The previous owner had planned to use the parts as samples to make molds. 017 remained apart until 2009 when the frame and all remaining parts returned to Germany for restoration. 906-017 will be shown in the form of it’s one and only race, the 1966 Daytona 24 Hours.

Gallery

Do you have a question?

Contact us to learn more about our restored vehicles and replacement parts. We are happy to help you!